With a background in machine design, the team at modsys are experts in factory automation. We provide services across the lifecycle of your assets from front end design through project management, detailed design, commissioning, optimisation and support.

PLC and HMI

modsys has extensive experience in designing and programming PLC and HMI systems across a range of industries. We have a library of standard functions which we use to develop systems that are:

- Robust – Proven by hundreds of thousands of operating hours.

- Flexible – Customisable to suit your unique applications.

- Maintainable – Easily followed by maintenance personnel.

- High Performance – Optimised for reduced bandwidth, scan time and memory consumption.

Our in-house design tools allow much of the software to be generated automatically, minimising development costs and ensuring a quality solution. We can develop systems based on all major platforms, including;

Robotic Automation

Industrial robots are increasingly being used to automate repetitive manual handling tasks in factory environments. modsys has developed a platform to interface robot controllers with the rest of the equipment on an automation network and avoid common issues:

- Enhanced User Interface – Monitor and control with full featured HMI and SCADA systems.

- Improved Maintainability – Avoid complex text based robot programming languages and utilise user friendly Function Block, Sequential Flow Chart and Ladder Logic languages.

- Increased Compatibility – Connect a wider range of equipment via field buses and extended IO capabilities.

- Machine Protection – Protect against collisions between the robot and external equipment.

The system is compatible with major robot manufacturers, such as;

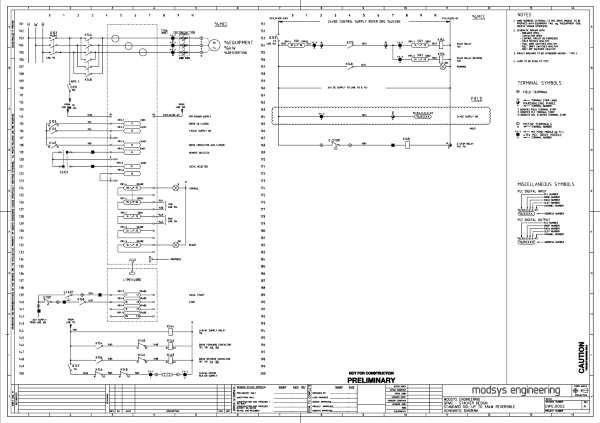

Electrical

As a core part of the integrated systems we deliver, modsys offers a complete electrical engineering service including:

- Electrical Drafting

- Electrical Equipment Selection

- Protection Analysis

- Electrical Demand Analysis

- Electrical Specifications

- Intelligent Protection Device Configuration

- Motor Control Centre Design

- Electrical System Testing

- Control System Interfacing

We also offer a range of standard PLC and distributed IO panels available in a range of sizes and configurations to minimise design costs.

Machine Safety

Depending on the complexity of your system, we can implement a cost effective solution based on:

- Safety relays

- Programmable controllers

- Safety PLCs

Vision Systems

Although a relatively new tool for factory automation, vision systems can greatly increase the intelligence of your equipment. The modsys team have the expertise to implement vision systems for:

- Part identification – Determine part types via markings, size and shape.

- Part location – Find the position and orientation parts to guide handling equipment.

- Defect inspection – Check part sizing, location, orientation and completion.

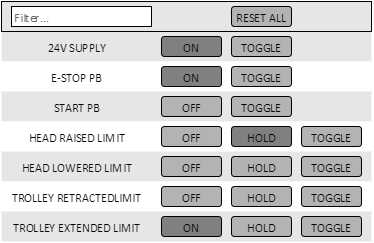

Simulation

As part of our design services, we have the facility to simulate your plant, be it an isolated machine or your entire factory, in our office environment. This enables us to validate the bulk of control system functionality before any site works commence. This ensures

- Reduced cost – Dramatically shortened site commissioning time.

- Reduced risk – Validate functionality without exposing personnel or machinery to damage.

- Increased reliability – Test handling of and recovery from common faults before they occur.

- Training – Familiarise personnel with the system without impacting production.

- Continued support – Replicate faults and test further improvements after initial commissioning.

Route Sequencing

Building on our experience gained in the mining industry, we offer route sequencing systems for your materials handling needs. Our systems automate and coordinate the control of conveyor networks

- Simplified Control – Monitor and control the entire system as a single device.

- Power Management – Reduce power consumption by slowing or stopping equipment when possible and minimise spikes in load by staggering equipment startups.

- Dynamic Route Planning – Select the shortest available path, working around equipment that is unavailable or out of service.

- Product Tracking – Monitor the distribution of materials around the system to track productivity and manage equipment loads.